The pharmaceutical industry is constantly evolving, with manufacturers seeking ways to optimize production processes while ensuring product safety and effectiveness. One emerging trend is the adoption of ready-to-use cartridges, which offer significant advantages over traditional bulk supplies. Understanding the cost-benefit analysis of this transition can help pharmaceutical companies make informed decisions about their packaging solutions.

Efficiency and Productivity Gains

Ready-to-use cartridges are engineered for seamless compatibility with automated filling lines, significantly enhancing operational efficiency. Unlike bulk supplies that require additional handling and preparation, ready-to-use (RTU) products minimize time spent on setup and reduce the risk of contamination. This streamlined process leads to faster turnaround times and allows for increased throughput in production facilities.

Pharmaceutical glass packaging companies that invest in RTU cartridges can expect substantial improvements in production reliability and productivity. With less manual intervention needed, the likelihood of human error is reduced, which directly contributes to better quality assurance and lower rates of defective products. This efficiency can translate to cost savings in labor and waste management, making ready-to-use cartridges an appealing choice for manufacturers looking to improve their bottom line.

Flexibility and Versatility

Another significant advantage of ready-to-use cartridges is their flexibility in meeting various application needs. Available in multiple sizes and configurations, these cartridges cater to a wide range of uses, including injections, biologics, and laboratory testing. This versatility provides pharmaceutical companies with the ability to adapt quickly to changing market demands and customer requirements.

By utilizing ready-to-use cartridges, manufacturers can also streamline their inventory management. Instead of maintaining a vast stock of various bulk supplies, they can consolidate their offerings into a selection of RTU products that serve multiple purposes. This not only reduces storage costs but also minimizes the complexity of supply chain logistics, resulting in a more efficient operational model.

Quality Assurance and Safety

Safety is paramount in the pharmaceutical industry, and ready-to-use cartridges often come with enhanced safety features compared to bulk supplies. The controlled manufacturing processes employed by pharmaceutical glass packaging companies ensure that RTU cartridges meet stringent quality standards. This compliance with regulatory requirements further instills confidence in both manufacturers and patients.

Moreover, the use of ready-to-use cartridges mitigates contamination risks inherent in bulk supplies, leading to a higher level of product integrity. By choosing RTU products, pharmaceutical companies can maintain their commitment to delivering safe and effective medicines to patients.

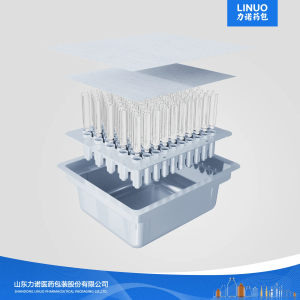

Strategic Partnership with Linuo

At Linuo, we recognize the significant benefits that ready-to-use cartridges can bring to the pharmaceutical industry. Our commitment to delivering premium, safe, and innovative packaging solutions positions us as a trusted partner for pharmaceutical glass packaging companies.

By adopting our ready-to-use cartridges, you will benefit from enhanced efficiency, flexibility, and quality assurance, all while helping to streamline your operations. As we continue to support your mission of bringing medicines to patients with confidence, we invite you to explore the advantages of transitioning to ready-to-use solutions with Linuo. Together, we can pave the way for a more efficient and effective future in pharmaceutical manufacturing.