As a company with nearly three decades of dedication to pharmaceutical glass manufacturing, we at LINUO have always believed that true innovation lies in meeting the evolving demands of the healthcare sector. The role of glass in pharmaceutical packaging is more crucial than ever before, as drug safety, stability, and global distribution standards continue to rise. Our integrated production chain, from high borosilicate glass tubing to finished ampoules, reflects our long-term commitment to delivering consistent quality and precision.

Redefining the Standard of Glass Ampoule Injection

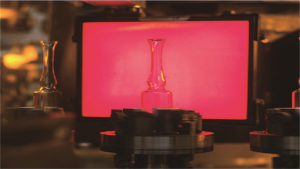

The future of injectable medicine depends heavily on the stability and purity of the packaging medium. That’s why our glass ampoule injection solutions are designed not only to meet international safety criteria but to exceed expectations in real-world clinical settings. We manufacture ampoules using high-quality borosilicate glass that is resistant to heat, shock, and chemical interactions—factors that can affect the efficacy of injectable drugs.

In our R&D processes, we focus on enhancing glass clarity, uniform wall thickness, and minimal extractables, so that the performance of the glass ampoule injection remains stable throughout shelf life and usage. More importantly, our designs offer compatibility with automated filling lines and break-off mechanisms that support efficient, sterile delivery. With increased emphasis on injectable therapies in chronic care and emergency medicine, the demand for trusted packaging solutions is greater than ever.

Innovation Across the Pharmaceutical Packaging Chain

In the evolving global market, the application of glass in pharmaceutical packaging is no longer limited to containment—it is part of the entire value chain that supports healthcare innovation. At LINUO, we integrate intelligent inspection systems into our production lines to ensure every ampoule meets rigorous visual and dimensional standards.

We also prioritize sustainability in our processes, reducing energy consumption during the glass melting and forming stages. By optimizing our use of raw materials and reducing waste, we make sure that our role in glass in pharmaceutical packaging contributes not just to safety, but to long-term environmental responsibility.

Furthermore, our scalable production capacity supports clients across multiple regions, with fast delivery and customizable packaging solutions that adapt to diverse pharmaceutical needs. Whether the requirement is for generic injectables or high-value biologics, our ampoules offer the strength, purity, and transparency that global pharmaceutical companies depend on.

Conclusion

At LINUO, we view glass in pharmaceutical packaging as a foundation for medical trust and innovation. Our expertise in glass ampoule injection enables us to provide solutions that align with international standards while addressing the nuanced needs of drug manufacturers. By combining quality materials, precision processes, and a deep understanding of industry expectations, we help ensure that every dose delivered through our glass solutions meets its purpose—safely, effectively, and consistently.

As we continue to grow and serve more clients worldwide, we remain committed to advancing the capabilities of pharmaceutical glass packaging, one ampoule at a time.