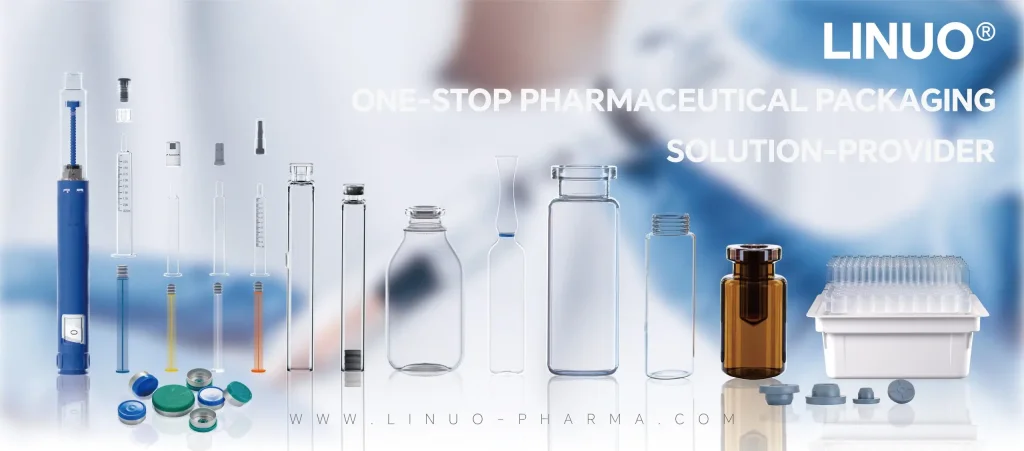

In today’s pharmaceutical industry, where quality and precision directly influence patient safety, packaging plays a vital role in ensuring drug stability and compliance. At LINUO, we are proud to contribute to this essential sector by offering high-performance tubular vials and moulded glass bottle solutions designed to meet the ever-evolving needs of pharmaceutical companies around the world. With three decades of expertise in pharmaceutical glass packaging, we have developed a full-cycle manufacturing system that ensures consistency, safety, and adaptability for a variety of medical applications.

Why Tubular Vials Remain a Critical Component

Among our core offerings, tubular vials have become a preferred choice for injectable packaging due to their superior dimensional accuracy and clarity. We manufacture these vials from high-quality borosilicate glass, ensuring low expansion, excellent chemical resistance, and stable performance across diverse conditions. These features are especially important for injectable drugs, where the interaction between packaging and medication must be tightly controlled.

Our tubular vials support a wide range of volumes and finishes, making them suitable for both large-scale production and small-batch specialty pharmaceuticals. What sets our vials apart is the precision shaping made possible by our in-house tubing and forming capabilities. As a company that controls the full production chain—from glass tubing to vial shaping—we ensure strict quality assurance at every stage, minimizing variations and maximizing reliability.

In addition to domestic markets, our tubular vials have gained increasing attention internationally, thanks to their compliance with major pharmacopeias and their ability to be integrated seamlessly into high-speed filling lines.

The Value of Moulded Glass Bottles in Diverse Applications

While tubular vials excel in precision-demanding injectable solutions, our moulded glass bottle offerings serve a different yet equally critical segment of the pharmaceutical packaging industry. Designed for high-volume and oral liquid medications, these bottles provide outstanding mechanical strength and resistance to thermal shock.

We produce moulded glass bottle types in both Type I and Type III glass categories to suit various medication stability requirements. With capacities ranging from 5 ml to 500 ml, these bottles are commonly used in cough syrups, antibiotics, and infusion fluids. Their durability and robustness make them ideal for packaging that faces frequent handling and long transportation cycles.

To accommodate specific client needs, we offer customizations in neck finish, bottle shape, and color. Whether the requirement is amber glass for UV-sensitive contents or a specific neck size for child-resistant closures, our moulded glass bottle options deliver reliable performance while ensuring regulatory compliance.

Conclusion

At LINUO, we believe that the future of pharmaceutical packaging lies in the balance between innovation and dependability. Our focus on producing high-quality tubular vials and moulded glass bottle solutions reflects our commitment to excellence, safety, and service. With our vertically integrated production lines, we are able to maintain consistent quality while offering the flexibility our clients need in today’s fast-paced global market.

As pharmaceutical demands continue to evolve, we remain ready to support our partners with reliable packaging that meets international standards. From injectable therapies to oral medications, LINUO is here to provide trusted solutions that help protect and deliver medicines safely to patients worldwide.